ALUMINUM FOIL THERMAL STRAPS

AlTS™

Because 1100 Al has roughly one third the density of copper and half the thermal conductivity, intrinsically there is a mass benefit of up to one third less for aluminum compared to copper straps. While our CuTS® and X-Series® products are often a better substitute for an Aluminum Foil Thermal Strap (AlTS™), there are some airborne and spaceflight applications which may benefit from an AlTS™ solution (particularly those that are extremely mass sensitive, operating at 50 - 70K, and with a relatively small amount of heat to dissipate).

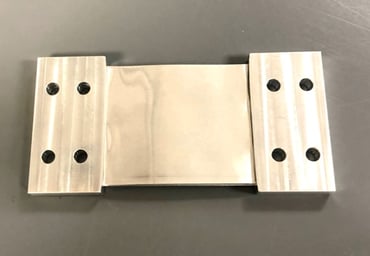

TAI now offers custom and standard model AlTS™. Like the F-Series Copper Foil Straps, all standard model AlTS™ are available in our 0.5", 1.0" and 2.0" wide models (our A5, A6, and A7-Series), with 0.001" stacks of Al1100 foils. They are length and bolt pattern customizable, and standard orders ship in just 6-7 weeks, while customs ship in 7-8 weeks.

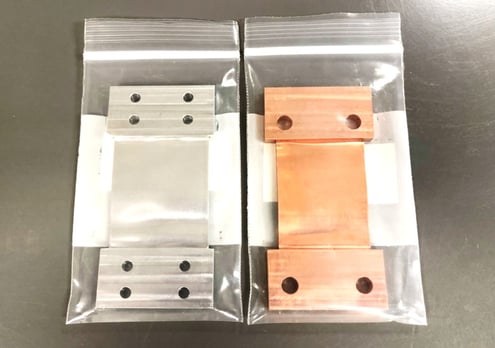

Pictured: A5-501 and F5-501 Thermal Straps being prepared for shipping (December 2018).

Limitations to Consider

Limitations to Consider

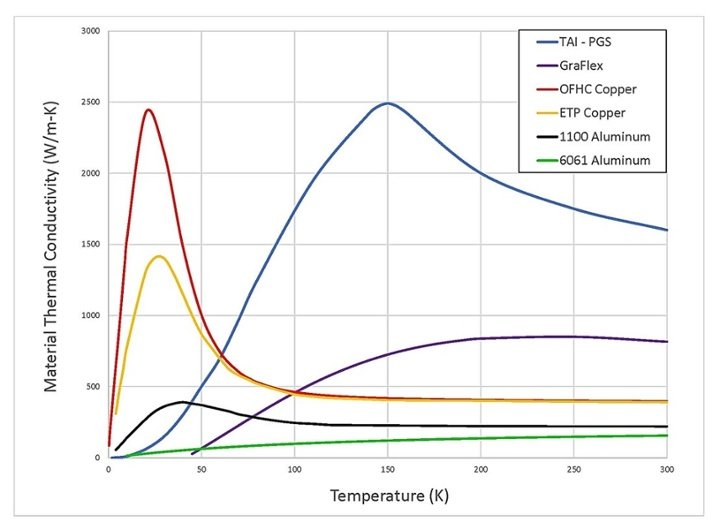

While aluminum foil-based straps can be an ideal solution in certain airborne and spaceflight applications, they have largely been replaced by TAI's CuTS® and PGL™ products. This is because our copper rope straps provide superior thermal performance and flexibility (at a lower unit cost), and our pyrolytic graphite film straps, TAI's X-Series® PGL™ (while slightly more expensive), offer superior thermal performance, at a small fraction of the mass of an equivalent aluminum link (down to operating temperatures as low as 50K). Furthermore, TAI's PGL™ products are made using the industry's highest performing carbon material at cryogenic temperatures.

Because 1100 Al has roughly one third the density of copper and half the thermal conductivity, intrinsically there is a mass benefit of up to one third less for aluminum compared to copper straps. However, there are a number of other factors to consider including:

1) Aluminum straps will occupy twice the volume of copper straps for the same thermal conductance.

2) Aluminum straps are limited to stacked-foil configurations that do not provide good flexibility on each axes. This means that curvature must be included in the thermal strap design to permit directional flexibility between the strap ends. When this is done, more mass and volume are added to the strap in order to maintain a specified thermal conductance, thereby reducing any benefit over copper braided thermal straps.

3) Aluminum readily forms an oxide that can greatly degrade thermal performance at interface locations without proper surface passivation measures.

4) Aluminum foil straps are far more expensive than TAI's CuTS®, and competing AlTS are the same price as TAI's GFTS® products.

5) Aluminum straps have more handling and integration constraints than copper rope straps.

To discuss an AlTS™ program, contact us today!

Comparison of Thermal Conductivity