COPPER THERMAL STRAPS (CuTS®)

OFHC COPPER CABLE FLEXIBLE THERMAL LINKS

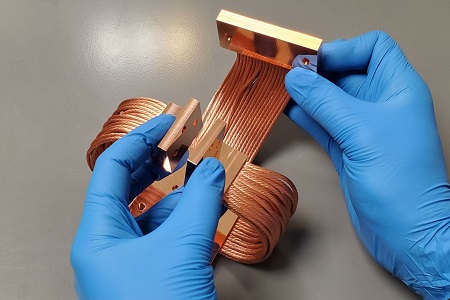

Thermal Straps made with copper cabling or braid (CuTS®), also referred to as "heat straps," "thermal braids," or "flexible thermal links," offer the optimal combination of flexibility, durability, vibration isolation, and efficient heat transfer (at an affordable price). OFHC copper-based thermal links are most often used in cryogenic applications (ranging from cryostats, to cryocoolers, cold boxes, cryomodules, and dilution refrigerators), due to their superior thermal performance at temperatures below 77K. However, due to their many benefits lower manufacturing cost (when compared to metallic foil or graphite & graphene-based straps), they are also a popular choice for passive heat transfer in warmer applications. As a result, aerospace & defense, semiconductor, imaging, and photonics organizations use them extensively in a wide range of equipment.

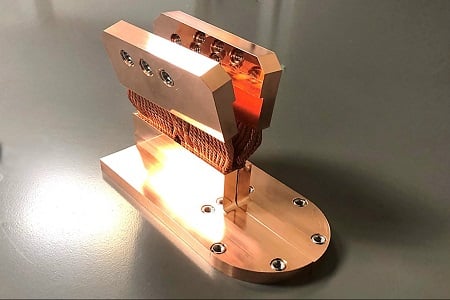

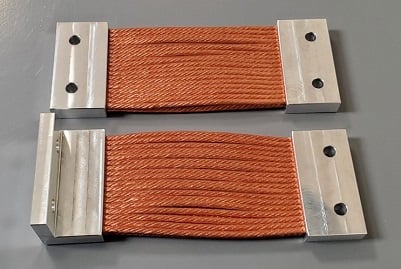

CuTS® are designed, manufactured, and tested here at TAI by our staff of engineers, technicians, and machinists. Our solderless, heat-free manufacturing process, refined over decades, optimizes flexibility while minimizing resistance losses. The result is a highly efficient thermal link; ideal for heat transfer at nearly any operating temperature, and offering superior vibration isolation over metallic foil and flat braid thermal straps, or welded shunts.

Whether you need a single strap for a focal plane, cryocooler, or cryostat, or thousands for particle accelerators, or military optical systems, you can count on the experts at TAI.

VISIT OUR DESIGN GALLERIES TO SEE HUNDREDS MORE!

THE MOST EFFICIENT & AFFORDABLE THERMAL STRAPS

Several factors make our copper strap products unique in the industry:

- In-House Manufacturing: most commercially-available links/straps on the market are outsourced and repackaged (welded) assemblies from third-parties. These products are stiffer than CuTS® (and can transfer vibration), plagued by dimensional non-conformities, tolerance & cleanliness issues, and offer poor performance at cryogenic temperatures. In-house fabrication—by a team of experienced technicians and machinists—ensures strict quality control. It also allows TAI to offer the lowest pricing in the industry, as well as a one-year warranty.

-

Cable Flexibility: each thermal strap is made with TAI's exclusive OFHC UltraFlex® I & II copper cabling, and our swage manufacturing process preserves cable flexibility.

-

Standard and Custom Designs: CuTS® are available in custom, and 127 standard models.

-

Gold & Nickel Plating: straps are available with nickel and gold plating options exclusive to TAI.

-

Space Flight Heritage: CuTS® are NASA TRL 9 and have extensive flight heritage on satellites, cubesats, and commercial crew and cargo vehicles.

-

Experience: The TAI team has a combined total of 100+ years of strap manufacturing, design, and qualification experience. We have designed and delivered more swaged copper (and graphite) thermal straps than any organization on the planet.

-

Manufacturing Capacity - TAI is the only supplier with the equipment, facilities, and technical, administrative, and manufacturing staff required to fill production orders. See our Production Program History section below for more details.

CuTS® CATALOG AND STANDARD PRODUCT LINE

TAI offers a fully-customizable standard line of thermal strap products and an annual edition of our CuTS® Catalog. The 2025 Catalog features 127 Standard and Cryocooler Series Models. However, fully custom designs account for more than half of our programs, and our engineering & machining staff can accommodate nearly any design request.

While standard models provide customers with the most affordable pricing and shortest lead times, custom units typically have the same unit pricing, only with a small NRE fee. To learn more about our other standard and custom strap offerings and materials, visit our Thermal Straps Product page.

|

STANDARD SERIES |

|

CUSTOM STRAPS |

CUSTOMIZATION OPTIONS AND CRYOCOOLER DESIGNS

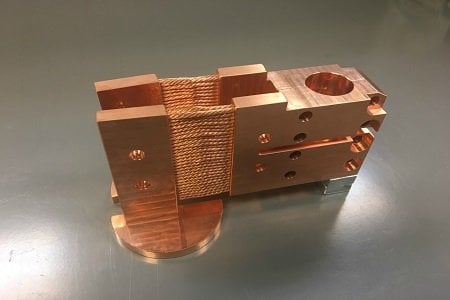

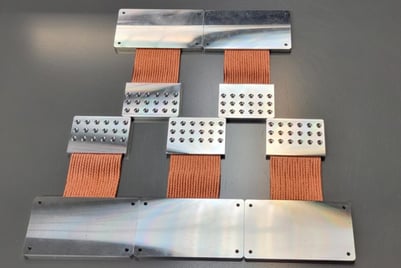

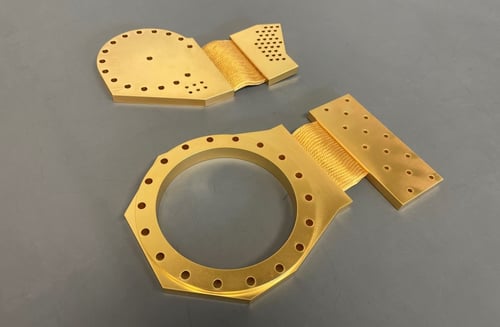

End fittings can be designed into a number of complex shapes, incorporating a wide range of features. However, some of the most commonly requested designs are disc or crescent-shaped end fittings (used on the first and second stages of cryocoolers), and TAI designs & manufactures hundreds of straps annually for Sumitomo, Cryomech, and SunPower cryocoolers. Other popular features include offset fittings, heat pipe interfaces, "c-clamp" and "battery terminal-type" fittings, nested configurations, and multiple-armed straps (with as many as 8 "arms").

|

Cryocooler Cold Head Fittings |

Multi-Armed Straps |

Cryocooler 1st Stage Fittings |

Heat Pipe Interface Fittings |

|

Offset End Fittings |

Mitered End Fittings |

Ring/1st Stage Fittings |

Electronics Box / Chip Interfaces |

OPTIMIZING & PREDICTING THERMAL STRAP CONDUCTIVITY

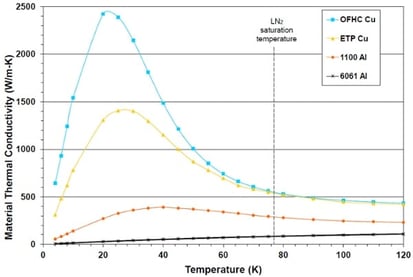

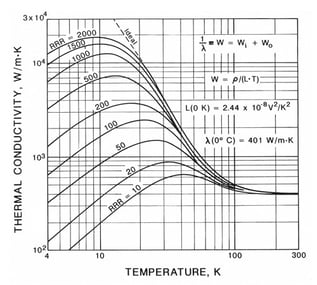

The conductivity of a thermal strap will depend on several key material, design, and environmental factors. In the case of OFHC copper, the material thermal conductivity will range from 397 W/m-K to nearly 2,500 W/m-K, at typical operating temps of 4K - 300K. As important as temperature is, design factors also impact the measured performance. The assembly process and other factors, such as the length of the cables, cable insertion depth, distance from the cables to the heat source and sink, and even the bolt patterns, play a role in the thermal conductivity of a strap assembly . As a result, thermal straps must be designed with all of these factors in mind, just as these factors need to be taken into account when predicting performance.

Our experience and strict quality control allow TAI to continuously refine our projection software and capabilities. We can provide highly-accurate performance projections from 2K, to 900K, accounting for contact resistance losses at the heat sink and source interfaces, and various thermal interface materials including eGraf, Sigraflex, or Indium foils.

RRR AND INCREASING STRAP CONDUCTIVITY AT CRYOGENIC TEMPERATURES

Making accurate conductance projections for any strap requires more than just an understanding of it's material thermal conductivity across a temperature gradient, however. The residual resistivity ratio (RRR) of the copper (in both the fittings and the cabling), will more accurately represent the thermal conductivity at cryogenic temperatures than the material purity alone (OFHC copper typically has a RRR between 50 - 100). Fortunately, TAI's copper thermal straps have been extensively tested by researchers at numerous US National Laboratories, and data shows a consistent RRR of 30-75, for the individual braid and plate materials and the strap assemblies as a whole.

Making accurate conductance projections for any strap requires more than just an understanding of it's material thermal conductivity across a temperature gradient, however. The residual resistivity ratio (RRR) of the copper (in both the fittings and the cabling), will more accurately represent the thermal conductivity at cryogenic temperatures than the material purity alone (OFHC copper typically has a RRR between 50 - 100). Fortunately, TAI's copper thermal straps have been extensively tested by researchers at numerous US National Laboratories, and data shows a consistent RRR of 30-75, for the individual braid and plate materials and the strap assemblies as a whole.

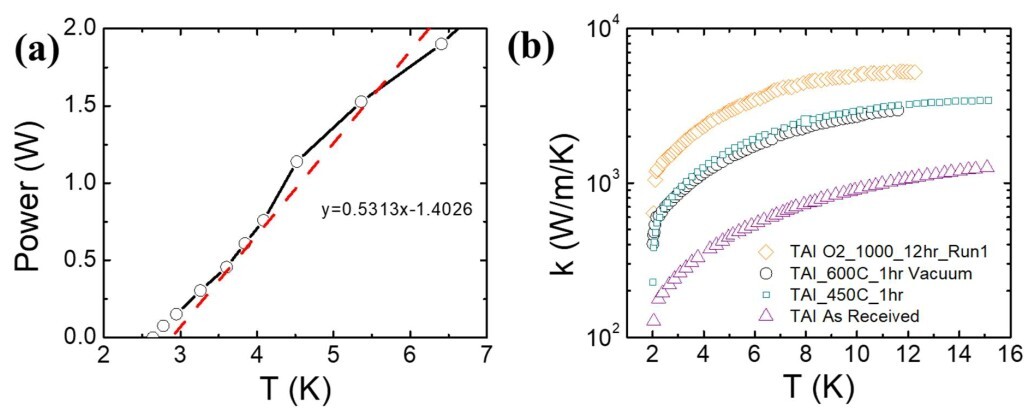

One of the most common questions we receive from our cryogenics customers is if TAI offers copper rope, plate, or foil products with a higher purity of 99.999 - 99.9999%, instead of OFHC's 99.99% (with RRR ranging from 150-300). Unfortunately, we do not, as those materials are exceptionally expensive and rope/cabling is generally only available in OFHC Cu. However, there is a much more affordable and simpler alternative should your application require additional thermal performance at cryogenic temperatures: CuTS® can always be vacuum annealed or e-beam welded to dramatically increase RRR using the process described by R.C. Dhuley et al.** (TAI does not offer these services but vacuum annealing is a very common practice and widely available to most of our customers). In fact, researchers at Brookhaven National Laboratory demonstrated that the thermal conductivity of our CuTS® products can be boosted at 4K by as much as 7X (to over 2,300 W/m-K) through vacuum annealing. To learn more about the RRR of OFHC copper and other materials, visit NIST's Cryogenic Material Properties Page, here.

**R. C. Dhuley et al.

Thermal conductance characterization of a pressed copper rope strap between 0.13 K and 10 K”, Cryogenics 86, 17-21, 2017.

Pictured (top right): Historical NBS measurements of copper thermal conductivity, (bottom): vacuum annealing test results on TAI's CuTS® products by Brookhaven National Lab in 2024..

Important Note: predictions assume the use of a TIM and account for interface resistance losses. Official predictions provided by TAI may also vary slightly from the calculator results, due to multiple design-related factors. For official conductance predictions for any custom or standard design, and at any operating temperature ranging from 1K - 600K+, contact TAI today. Additional predictions at different operating temps are available in the catalog.

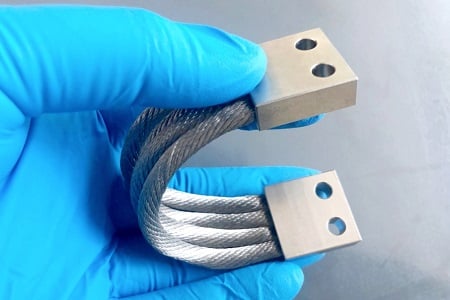

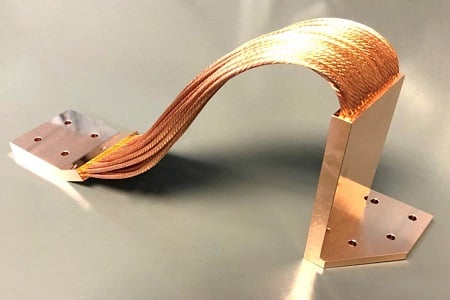

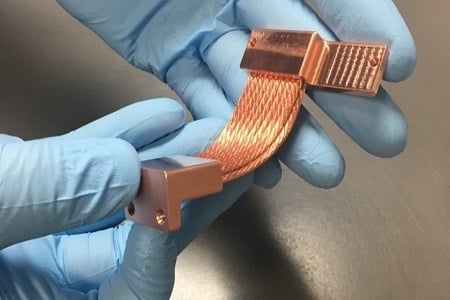

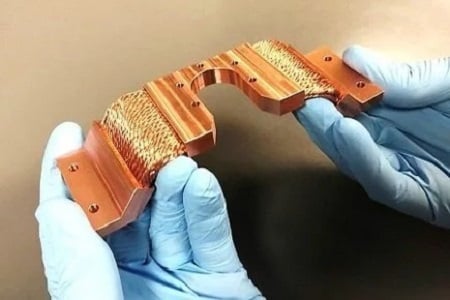

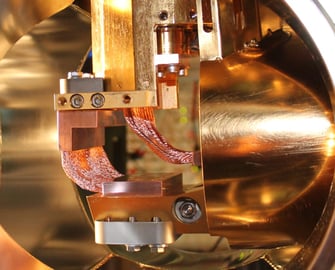

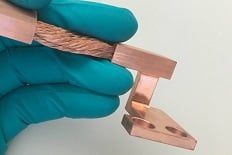

SUPERIOR VIBRATION ISOLATION - OFHC ULTRAFLEX™ I & II CABLING

To optimize the vibration isolation capabilities of our copper thermal straps, TAI developed two custom cable types with our braid supplier: OFHC UltraFlex™ I and II. Due to the unique assembly process of these cables, which use hundreds of extremely fine individual wires wrapped into multiple smaller cables (that are then wrapped around each other and a central core), thermal linkages made with OFHC UltraFlex™ offer the highest degree of flexibility and vibration isolation available on the market. Because of this (and their efficiency), dozens of scholarly articles in journals ranging from Cryogenics, to the Review of Scientific Instruments, have featured papers mentioning CuTS®. The list below details just a small number of these papers:

To optimize the vibration isolation capabilities of our copper thermal straps, TAI developed two custom cable types with our braid supplier: OFHC UltraFlex™ I and II. Due to the unique assembly process of these cables, which use hundreds of extremely fine individual wires wrapped into multiple smaller cables (that are then wrapped around each other and a central core), thermal linkages made with OFHC UltraFlex™ offer the highest degree of flexibility and vibration isolation available on the market. Because of this (and their efficiency), dozens of scholarly articles in journals ranging from Cryogenics, to the Review of Scientific Instruments, have featured papers mentioning CuTS®. The list below details just a small number of these papers:

-

Closed-cycle, low-vibration 4 K cryostat for ion traps and other applications

-

Thermal conductance modeling and characterization of the SuperCDMS SNOLAB subKelvin cryogenic system

-

Flexible linkages for thermal management at cryogenic temperatures

- Stable CW Operation of Nb3Sn SRF Cavity at 10 MV/m using Conduction Cooling

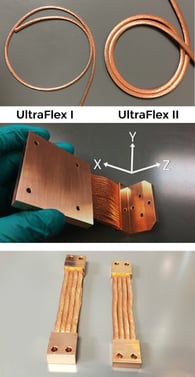

OFHC UltraFlex™ I is our exclusive 0.10 in (2.5 mm) diameter cabling. It was developed by our engineers in 2016, and is only available from TAI. CuTS® assemblies made with OFHC UltraFlex™ cabling offer >65% flexibility on the compression axis (X), and >25% flexibility on the Y and Z axes over other commercially-available thermal straps and shunts using braided materials.

OFHC UltraFlex™ I is our exclusive 0.10 in (2.5 mm) diameter cabling. It was developed by our engineers in 2016, and is only available from TAI. CuTS® assemblies made with OFHC UltraFlex™ cabling offer >65% flexibility on the compression axis (X), and >25% flexibility on the Y and Z axes over other commercially-available thermal straps and shunts using braided materials.

OFHC UltraFlex™ II is our 0.20 in (5 mm) diameter copper cabling. UltraFlex II is unique in the industry, is only available from TAI, and is the industry's most flexible 0.20 in diameter cabling. This cabling is ideal for customers with larger heat dissipation needs with the available volume to accommodate thicker end fittings.

TAI's CuTS® products using OFHC UltraFlex have successfully passed multiple life cycle flex tests of up to 1 Million flex cycles on the compression axis. To view videos of the life cycle flex tests, click here now.

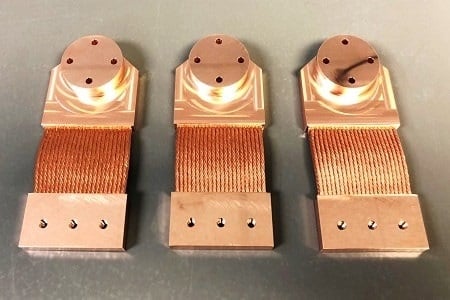

Pictured: TAI CuTS® Models P60-501 and P60-502, using our exclusive OFHC UltraFlex™ II (July 2019).

ALUMINUM FITTINGS

Aluminum 6061 end fittings are available on most of our standard and (some) custom copper strap products (there are limitations with specific end fitting designs and with straps that have a relatively short, double row of cables). Aluminum fittings are 70% lighter than their copper counterparts and have a negligible impact on thermal performance. This option is available at no additional cost. Our expert technicians can also directly integrate OFHC UltraFlex Cabling into aluminum cold plates and other components.

IMPORTANT UPDATE - As of October 14, 2024, TAI can now publicly confirm our Hybrid Cu-Al CuTS® products have Space Flight Heritage on NASA's Europa Clipper Mission (we were unable to disclose other, confidential programs using these products), as well as ESA's Proba-3, and several missions scheduled to launch in December 2024 and throughout 2025, advancing them to NASA TRL 9.

|

|

|

Pictured: (left) Custom Hybrid CuTS® with Al 6061 fittings (customer name/program withheld); (center) Custom Hybrid CuTS® used on SUrface Dust Analyzer instrument on the Europa Clipper Mission (March 2019, launched October 2024), (right) Hyrbrid P5-502 and P5-505 CuTS® (customer name/program withheld).

GOLD & NICKEL PLATING

Copper Thermal Straps can be plated with gold or nickel (among other materials used as diffusion barriers). However, there are several important factors to consider. For example, most commercial plating vendors will only plate to a minimum thickness of 0.002 inches. At this thickness, the cables will become so stiff that they can transfer vibration. They may also have difficulty accommodating your deflection or range of motion requirements. Additionally, special precautions need to be taken to properly clean thermal straps, in order to remove any remaining chemicals or plating salts.

Copper Thermal Straps can be plated with gold or nickel (among other materials used as diffusion barriers). However, there are several important factors to consider. For example, most commercial plating vendors will only plate to a minimum thickness of 0.002 inches. At this thickness, the cables will become so stiff that they can transfer vibration. They may also have difficulty accommodating your deflection or range of motion requirements. Additionally, special precautions need to be taken to properly clean thermal straps, in order to remove any remaining chemicals or plating salts.

For customers requiring gold plating, we offer multiple diffusion barrier options (both magnetic and non-magnetic), and straps can be plated to certain ASTM standards (B-488 Type I & III, Code C & D, for example). However, our most popular gold plating option is TAI's "Lab Grade" plating (99.7% pure gold on top of a non-magnetic diffusion barrier).

Due to its low oxygen affinity, gold plating of copper fittings and cables is a highly effective solution to prevent oxidation and achieve electronic thermal conductance across interfaces. Additionally, surface oxide of gold breaks at a low applied load, thereby giving a larger probability of achieving a metallic contact. Gold also has a lower surface hardness than copper, and as a result, gold plated contacts have a larger area of physical contact, and therefore, lower thermal resistance for a given applied force. Gold plating also is used to minimize the absorption of radiant heat, and TAI's gold plating options offer the lowest surface emittance in the industry.

Click Here to See our New Nickel & Gold Plated Strap Design Gallery

|

|

|

|

Pictured (Top Left): Custom Thermal Straps designed for a Cryomech PT cryocooler's 4K and 50K stages (September 2023).

SPACE FLIGHT HERITAGE

The list below details just a handful of the missions that use our Copper Thermal Strap products:

The list below details just a handful of the missions that use our Copper Thermal Strap products:

-

Lockheed Martin/NOAA's GOES-R - Launched November 2016

-

NASA's OSIRIS REx - Launched September 2016

-

Numerous Department of Defense Satellites (Program Names Withheld) - Launched 2016 - 2025

-

NOAA's GOES-S/T/U - Launched 2017 - 2019 and beyond

-

NASA's GRACE-FO - Launched 2018

-

Orbital ATK's Cignus OA-9 Spacecraft - Launched May 2018

-

NASA's GEDI Sensor (on board the ISS) - Launched December 2018

-

Eumetsat's METEOSAT - Launched December 13, 2022

-

NASA JPL's Deep Space Atomic Clock (DSAC) - Launched June 22, 2019

-

ESA's Solar Orbiter - Launched February 10, 2020

- ESA's Jupiter Icy Moons Explorer (JUICE) - Launched April 14, 2023

- NASA's Europa Clipper Mission - Launched October 14, 2024

Between 2016 - 2024, TAI provided over 7,000 prototype, "proto-flight," and flight model (FM) Copper Thermal Straps for numerous space programs. Additionally, our straps are found on nearly all commercial crew/manned, and cargo spacecraft in the USA. Our customers include: NASA, ESA, Lockheed, Airbus, Raytheon, OHB, Thales, L-3, Honeywell, Harris Corp., MIT, Orbital ATK, Surrey Satellite (SSTL), Northrop Grumman, ABB, Micos, and many others we are not at liberty to disclose due to non disclosure agreements.

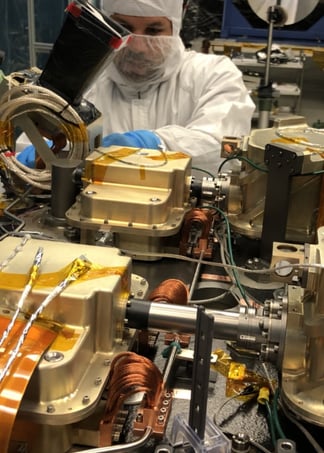

Pictured: NASA Engineer prepares the GEDI Sensor for launch with Heat Pipe Interface CuTS® (2018).

PRODUCTION PROGRAM HISTORY

The list below details a small sample of our production (300 - 5,000+ unit) programs:

- BAE Systems Vehicle Mounted Optical System (program name withheld) - (2014 - 2019) - TAI delivered nearly 1,000 custom units for optical systems mounted to aircraft and military vehicles.

- Department of Energy (program name withheld) - (2014 - 2021) - TAI delivered over 1,500 custom units to the DoE.

- Customer Name Withheld - Autonomous Vehicle Fleet Program - (2017 - 2019) - TAI delivered nearly 3,000 custom units as part of a custom cooling system for autonomous vehicle fleets.

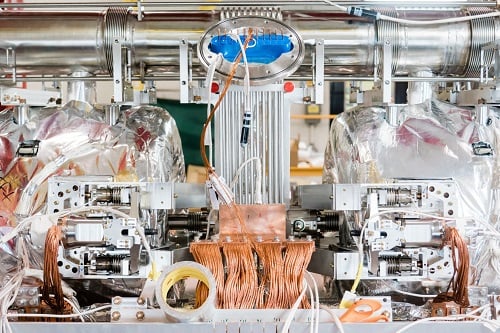

- SLAC's LCLS-II - (2016 - 2017) - TAI supplied nearly 3,000 standard models for the cryomodules used in the LCLS-II over 18 months.

- Argonne Lab's APS-U (2020 - 2022) - TAI supplied over 600 standard and custom units for 4 cryostats that are used by the superconducting undulator beam chamber as part of the Advanced Photon Source Upgrade Project (APSU).

-

SLAC's LCLS-II-HE - (2021 - 2022) - TAI supplied nearly 1,500 standard models for the cryomodules in the LCLS-II-HE upgrade over 2021-2022.

- Fermi Lab's PIP-II - (2018 and 2021) - TAI supplied over 300 custom and standard models for the SSR1 and HB650 Cryomodules as part of the Proton Improvement Plan (PIP-II) program.

- Bhabha Atomic Research Centre (India) - TAI supplied over 500 gold plated standard models for a cryogenic research program at BARC (2021).

- Department of Energy (program name withheld) - TAI supplies over 2,500 custom units to the DoE between January 2022 - December 2024.

- Name Withheld - Mining and Oil/Natural Gas Equipment - TAI supplies over 3,000 custom units to an international oil and mining equipment manufacturer between Spring 2022 and 2024.

- Customer Name Withheld - Commercial Spaceflight/Satellite Programs - TAI supplies over 3,000 standard models to commercial space flight company for multiple missions between January 2022 and December 2024.

Pictured: SSR1 Cryomodule used by Fermi Lab (photo credit FNAL.gov) |

Pictured: CuTS® mounted inside an SSR1 Cryomodule (photo credit FNAL.gov) |

UNIVERSITY RESEARCH PROGRAM

TAI offers unique partnership and support opportunities for our university (and some) national laboratory customers. From exclusive offers and reduced pricing, to complimentary design and manufacturing services for university Physics and Aerospace Engineering programs, our team is happy to help!

TAI also offers free straps to a select group of university programs annually, in addition to these discounts. Visit our University Showcase Page for a small sample of previous participants in our program. Contact TAI today to learn more.

Pictured: TAI's P5-505 model thermal straps used in an Ion Penning Trap Experiment at the University of Granada's UGR Lab.

DESIGNING & ORDERING YOUR STRAPS

If you have already selected your standard model(s) from the catalog, please download and complete our Questionnaire and Ordering Form and send it to our Director of Business Development at tlink@techapps.com, to receive your quote.

The design phase starts once our Design Engineers have your questionnaire and STP files detailing the interfaces and envelopes for each strap location. Once a design is ready, STP files are provided to the customer, as are performance and pricing projections. All of this happens prior to creating your quote, so you know exactly what you are getting before spending any money.

THERMAL STRAP FAQ

How Much do Thermal Straps Cost?

The price of a strap is heavily dependent upon a number of factors. These include quantity, conductive material used, design complexity, and plating. Program testing & reporting requirements are also important, and can increase the price dramatically. In general, most copper cabled straps may cost as little as one hundred dollars to as much as a few thousands of dollars or more per unit. However, graphite and graphene-based straps typically cost thousands of dollars each. This is due to the NRE and expensive materials required for each assembly.

Important note: TAI provides all strap design and consulting services at no charge. We do this so our customers know exactly what they are getting before an order is ever placed.

What is the RRR of your Copper?

TAI only uses OFHC copper (C101) in our CuTS products. The purity of the plate and rope material will range from 99.99% - 99.998%. Unfortunately, we have no control over what we receive from our suppliers, and there is no commercially available cable/braid material with a higher purity.

In general, OFHC copper will have a RRR of 50-100. While TAI cannot verify RRR on-site, a number of our customers at national laboratories have, since 2016. In numerous tests, our CuTS® assemblies have been shown to have a RRR of 50-75.

If a higher RRR is needed, customers can always vacuum anneal straps.

Can you Gold Plate Just the Fittings?

While it is possible to only plate the fittings of a copper thermal strap, there are two reasons why TAI only plates the entire assembly:

1. Unless the strap is extremely long (with a large number of ropes), there is little to no cost savings to be had in only plating the fittings. While less plating material is used--even though it may be very expensive--any material savings is typically offset by the fact that the labor hours are doubled (because the plater must properly mask and plate only the fittings).

2. Even when the fittings are masked from the ropes as best they can be, there will still be some plating chemicals/salts and metals that wick up the cables. This leads to a discoloration of the first ~10-15mm of the ropes on each end, giving them a darkened appearance. While this does not impact the thermal performance, it can lead to concern with some customers. As a result, we only plate the entire strap to avoid any issues or customer complaints.

Which Thermal Interface Materials Should I use to Improve Performance?

Apiezon Grease, Indium Foils, and SigraFlex are common choices for many laboratory and spaceflight applications. However, TAI prefers to use eGraf's HT1205 material, as it is the most efficient we have used in over a decade of testing.

How do you Properly Clean Thermal Straps for Vacuum and/or Space Applications?

Typically, all thermal strap assemblies are either ultrasonically washed and rinsed, or vacuum baked to remove any remaining contaminants.

While we perform an ultrasonic rinse on all of our copper straps (using Simple Green as a degreaser and reverse osmosis water), we do not clean to a particular spec. Thus, we always recommend our customers run their own round of ultrasonic cleaning (most use IPA, acetone, or alconox), or they perform a vacuum bake out, prior to install. The most popular spec for aerospace applications tends to be 24 hours at 150C, P=5.0E-9 mBar.

Additionally, straps using our larger UFII cabling will need to go through additional rounds of rinsing in RO or distilled water. This is because the thicker, "spongier" cable can soak up more of the degreaser and cooling/cutting fluid. It also has more surface area within the cables than the smaller UFI cabling. This does not always result in retained/trace amounts of fluids or contaminants within the UFII cabling, but it has happened on one occasion.

What Testing Services does TAI Offer?

TAI provides a comprehensive range of strap testing services to our customers. Some of which are complimentary, and other services are offered at an affordable rate and performed either here at our facility, or by one a third party like NTS or AstroPak. Each assembly will go through numerous quality checks during and after construction to verify requirements compliance and build quality. TAI's Management, Engineers, and Program Managers have extensive experience with the Quality Assurance processes and qualification that is required by the industry's top primes, NASA, ESA, and JAXA.

Pictured (Above): Custom UHV Chamber CuTS® [Post-Polishing] (1/9/18). (Left): Custom FM CuTS® - ESA Solar Orbiter (February 2016).

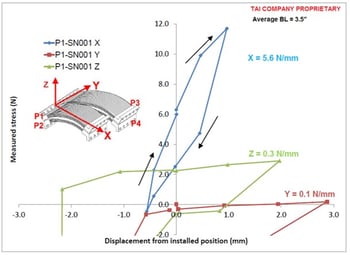

Does TAI Provide Strap Flexibility Demonstrations & Stiffness Data?

Check out our Copper Strap flexibility demonstration videos.

TAI also offers stiffness graphs taken from several custom and standard model copper thermal straps we've manufactured. While the data is not a guarantee of performance in your own design (as stiffness is a function of multiple variables), it can provide you with a rough understanding of what to expect (in N/mm, on each axis).

Contact TAI for more information.

Other Strap Manufacturing & Integration Capabilities

Thermal straps also provide mechanical decoupling and vibration damping in systems which are designed around vapor chambers and heat pipes. While our traditional approach is to design the ideal fittings, TAI can (in many cases), press our copper cabling directly into the structure of a cold plate, heat pipe, or vapor chamber. Thereby eliminating the additional joints and subsequent resistance losses from fittings.

Thermal straps also provide mechanical decoupling and vibration damping in systems which are designed around vapor chambers and heat pipes. While our traditional approach is to design the ideal fittings, TAI can (in many cases), press our copper cabling directly into the structure of a cold plate, heat pipe, or vapor chamber. Thereby eliminating the additional joints and subsequent resistance losses from fittings.

TAI can design and manufacture various adapter blocks, brackets, clamps, cold plates, and other structural components as needed. These parts are made using a wide range of materials, though OFHC Cu and Al 6061 are the most common. While it may make sense for some customers to machine their components (as is the case with many of our university customers), TAI can often provide these components at a lower unit cost than if they were machined (internally) by most of our aerospace customers.

TAI can design and manufacture various adapter blocks, brackets, clamps, cold plates, and other structural components as needed. These parts are made using a wide range of materials, though OFHC Cu and Al 6061 are the most common. While it may make sense for some customers to machine their components (as is the case with many of our university customers), TAI can often provide these components at a lower unit cost than if they were machined (internally) by most of our aerospace customers.

Pictured (Left): FM CuTS® With Adapter/Extension Arms - Parker Solar Probe, NASA. Pictured (Right): TAI's Flexible Vapor Chambers (integrated directly with OFHC UltraFlex™ Cu Cabling).

%20-%20ASML%20Cryocooler%20-%20450x300.jpg?width=317&height=211&name=Gold%20Plated%20Copper%20Thermal%20Strap%20(CuTS)%20-%20ASML%20Cryocooler%20-%20450x300.jpg)