Al & Cu FOIL THERMAL STRAPS (CuFS®)

(Products Discontinued)

Generally, thermal straps made with copper cables offer the best combination of durability, flexibility, thermal performance and low cost. This is because metallic foil straps are stiff, expensive, and need to be manufactured into longer, heavier, and less efficient installation configurations with 180 degree bends or S-shapes to allow for flexibility/deflection on the lateral axis (to learn more about which strap configuration best meets your needs, visit our Thermal Straps page). However, there are instances where flexibility is not needed in all 3 axes, and tight packaging constraints (limited volume), low operating temperatures, and high thermal conductance requirements, may make an OFHC copper foil thermal strap (CuFS®) a superior alternative to cu rope or graphite straps.

Though TAI offered (limited) custom CuFS® products since 2014, and our first standard line, the “F-series,” in 2016 - 2020, we have officially discontinued our metallic foil strap lines.

This decision was due to a lack of demand, as our copper and aluminum-copper hybrid straps offer exponentially greater flexibility at a lower unit cost than foil straps (while we manufacture several thousand copper cable straps annually, we never made more than a few foil straps each year), and because copper and aluminum foil straps significantly slowed down our production process with the technicians and machinists.

As a result, if we cannot substitute a copper cable or graphite rope or sheet strap that will meet your needs, we are happy to provide you with referrals to other suppliers that still offer foil straps and manufacture the products they sell (rather than outsourcing cheap welded shunts or poor quality links from third parties).

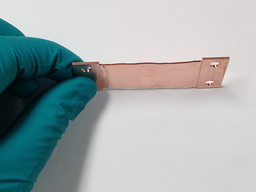

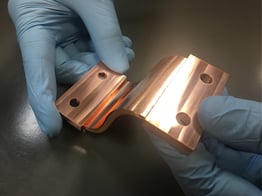

Pictured (Top Right): LAB GRADE Gold Plated Copper Foil Thermal Strap (November 2018). Pictured (Left): Custom, Low Profile, Foil Thermal Strap (July 2013).

CuFS® Standard Product Line - Discontinued

TAI now offers 6 standard models, and our full line of 24 standard models (and the new CuFS™ Catalog). TAI provides our newest copper thermal strap products in 3 fixed widths, with multiple thickness, installation configuration/design options, and with many of our popular end fitting designs. Just like our cabling/rope straps, these straps can be manufactured and shipped more quickly than custom straps (4 - 6 weeks on average).

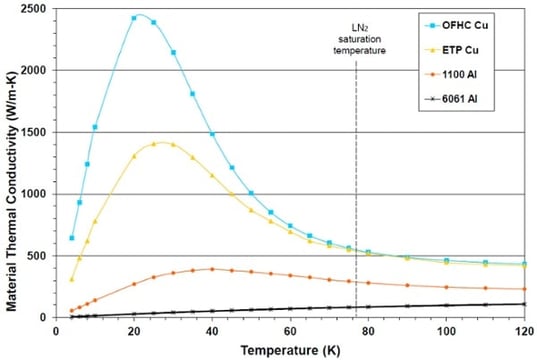

Comparison of Thermal Conductivity

|

|

Pictured (Top Left): conductivity graph of typical cryogenic thermal strap materials. (Top Right): F5-501 CuFS® pre-conductance test and shipping (April 2018).