TESTING SERVICES

Technology Applications, Inc. provides a wide range of strap testing services for our clients, both in-house, and with our test facility partners in Boulder, CO, and Southern California. From thermal conductance testing, to thermal cycling, stiffness, tensile strength, shock and vibration testing, our trained staff and test facility partners have the tools and experience required to test your straps to nearly any spec.

Technology Applications, Inc. provides a wide range of strap testing services for our clients, both in-house, and with our test facility partners in Boulder, CO, and Southern California. From thermal conductance testing, to thermal cycling, stiffness, tensile strength, shock and vibration testing, our trained staff and test facility partners have the tools and experience required to test your straps to nearly any spec. While some testing is complimentary and included in certain orders, other tests can be added to your program for reasonable rates, if desired.

Our sister organization, TAI, Inc. (www.tai-inc.us) also will begin providing some thermal strap testing services for Technology Applications, Inc., in addition to their thermal strap R&D and Government Contracting work. To learn more about the testing and qualification services offered, see below, and please feel free to call us at any time.

Thermal Conductance Testing

Thermal Cycling

Contact us to discuss your specific requirements. More information on our Thermal Cycling Test Services will be coming shorty. To discuss your specific testing needs, contact TAI today.

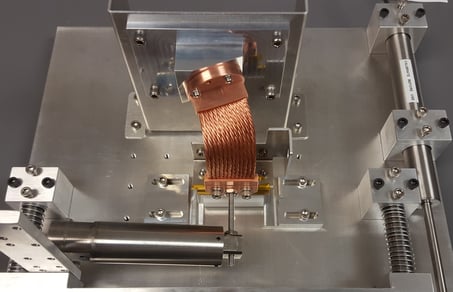

Stiffness Testing

With all stiffness tests, unique tooling is designed and used to test the strap’s stiffness in any desired position for all axes. Any positive or negative displacement relative to the strap’s neutral position can be measured, and the force and displacement is measured using NIST traceable calibrated transducers. To learn more about our stiffness testing services, and for sample stiffness test data on previous copper and graphite thermal straps, please contact us today.

Pictured (above): custom copper flight strap (METEOSAT) undergoing stiffness testing at TAI (April 2016).

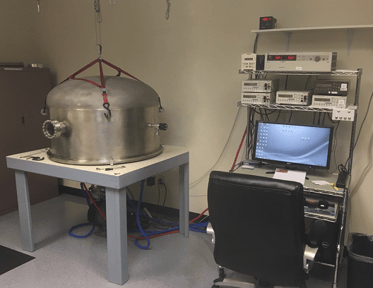

Shock & Vibration Testing

Pictured (left): custom copper flight strap (NASA GRACE) undergoing vibration testing.

To learn more about our thermal strap offerings, or if you have an inquiry about a current or future program, contact us at any time. Our Marketing and Sales Department is available 7 days/week, from 06:00-22:00 MST (13:00-05:00 GMT).