The TAI team is thrilled to announce we have completed a development program for NASA, which focused on providing a passive cooling solution with the lowest allowable stiffness requirement ever applied to a thermal strap/flexible thermal link, in NASA's history.

Pictured: X6-501 Thermal Straps with and without Mylar® sleeves, mounted in shipping fixtures.

This development contract focused on our X-Series® (PGS-type) thermal strap products (and used our X6-501 model strap). The goal was to be able to provide a highly conductive, low mass, "near-zero stiffness" strap solution for an extremely sensitive spaceflight instrument on a current satellite program (more details coming 2019).

TAI manufactured multiple X-Series® thermal straps for NASA as part of the program, and also provided stiffness and thermal conductance testing of the various designs/iterations.

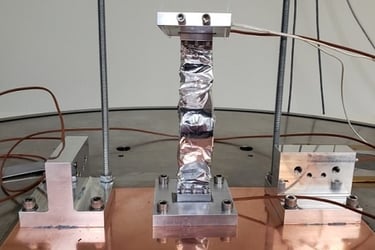

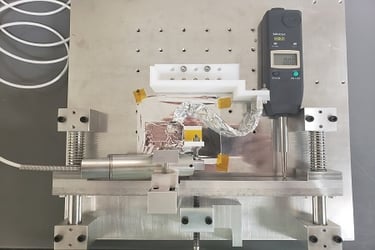

Pictured: Thermal Conductance Test (Test Chamber #1), and Stiffness Test on Encapsulated X-Series® Thermal Straps.

Tests demonstrated that TAI's X-Series® PGL™ Thermal Straps not only met NASA's extremely small mN/mm requirements; they exceeded all expectations and came in below, or at a fraction of the requirement (and on each axis), based on certain design variations and installation configurations. They also provided nearly 4X the thermal performance of comparable Copper Rope and Graphite Fiber Thermal Straps.

We look forward to beginning work on the EM and FM X-Series® straps in the coming months, and thank NASA for this opportunity to (potentially) make history (and I personally, want to thank our team for all of their hard work).

More details to come...